10 years of experience as a food machinery equipment manufacturer

10 years of experience as a food machinery equipment manufacturer

The culinary world continuously seeks innovations that enhance flavor, improve texture, and streamline preparation processes. One such advancement that has significantly impacted food marination is the vacuum tumbler marinator machine. Traditionally, marination involves soaking food, typically proteins like meat, poultry, or fish, in a seasoned liquid for extended periods. This static method often results in uneven flavor penetration and can be very time-consuming. The vacuum tumbler marinator addresses these limitations by employing a combination of vacuum technology and mechanical action to expedite and intensify the marination process, leading to superior product quality.

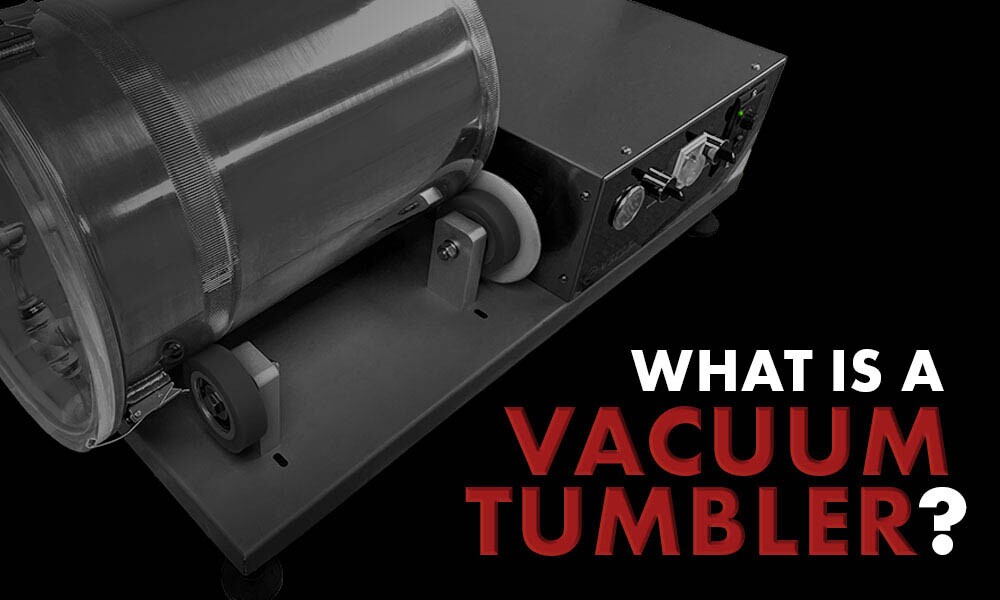

At its core, a vacuum tumbler marinator machine consists of a rotating drum or chamber connected to a vacuum pump. The food product, along with the marinade, is placed inside this drum. The process begins with the vacuum pump evacuating air from the drum, creating a low-pressure environment. This vacuum helps to remove air from within the food’s cellular structure and from between muscle fibers, effectively opening up pores. Once the desired vacuum level is achieved, the drum begins to rotate or ‘tumble’. This gentle yet persistent mechanical action massages the marinade into the food. The pressure differential created facilitates the absorption of the liquid deep into the tissues. The tumbling also contributes to the breakdown of tougher muscle fibers, enhancing tenderness. This synergy of vacuum and tumbling ensures rapid, deep, and even marinade absorption.

The adoption of vacuum tumbler marinators offers a multitude of benefits, translating into improved product quality and operational efficiency.

Vacuum tumbler marinators are versatile tools, finding utility across various segments of the food industry.

Commercial Kitchens: Restaurants and catering services leverage these machines for accelerated preparation times and consistent, high-quality marinated dishes. This allows chefs to enhance menu offerings, especially those centered around grilled or roasted proteins, while ensuring reliable flavor profiles.

Butcher Shops and Delicatessens: These establishments use vacuum tumblers to create value-added products like pre-marinated steaks, chicken pieces, or sausages. This offers customers convenient, flavor-enhanced options and can improve the shelf appeal and tenderness of various cuts.

Food Processing Plants: In large-scale operations, industrial vacuum tumblers are essential for marinating, curing, and seasoning large volumes of meat, poultry, and seafood. They contribute to standardized product quality, maximized yields, and overall production line efficiency for items destined for retail or food service.

Smaller countertop models also make this technology accessible to specialty food producers and dedicated home cooks seeking professional-grade marination results.

Selecting an appropriate vacuum tumbler marinator involves evaluating several key features to match operational needs.

A thorough assessment of these aspects ensures the chosen machine will be a productive and lasting investment.

The integration of vacuum tumbler marinator machines into food preparation workflows brings about a tangible improvement in the final product’s quality. Proteins become consistently more flavorful, with marinades penetrating deep beyond the surface, and a marked increase in tenderness is often observed. This leads to a more enjoyable eating experience. From a business perspective, the benefits extend to operational efficiency. Reduced marination time allows for faster product turnaround, while increased yields can contribute positively to cost management, ultimately impacting profitability.

In summary, the vacuum tumbler marinator machine stands as a significant technological asset in modern food processing and culinary arts. By effectively combining vacuum science with mechanical tumbling, it provides a superior method for marinating diverse food products. The resulting improvements in flavor depth, texture, consistency, and processing speed make it an invaluable tool for businesses and culinary professionals aiming to achieve optimal marination outcomes and enhance overall product quality.