10 years of experience as a food machinery equipment manufacturer

10 years of experience as a food machinery equipment manufacturer

The meat processing industry continually seeks methods to enhance product quality, improve operational efficiency, and meet consumer demand for flavorful and tender meat products. Marination, a traditional technique for infusing flavor and improving texture, has evolved significantly with technological advancements. Among these innovations, the meat vacuum tumbler machine stands out as a critical piece of equipment for commercial meat processors, offering a sophisticated approach to marinating and processing various types of meat.

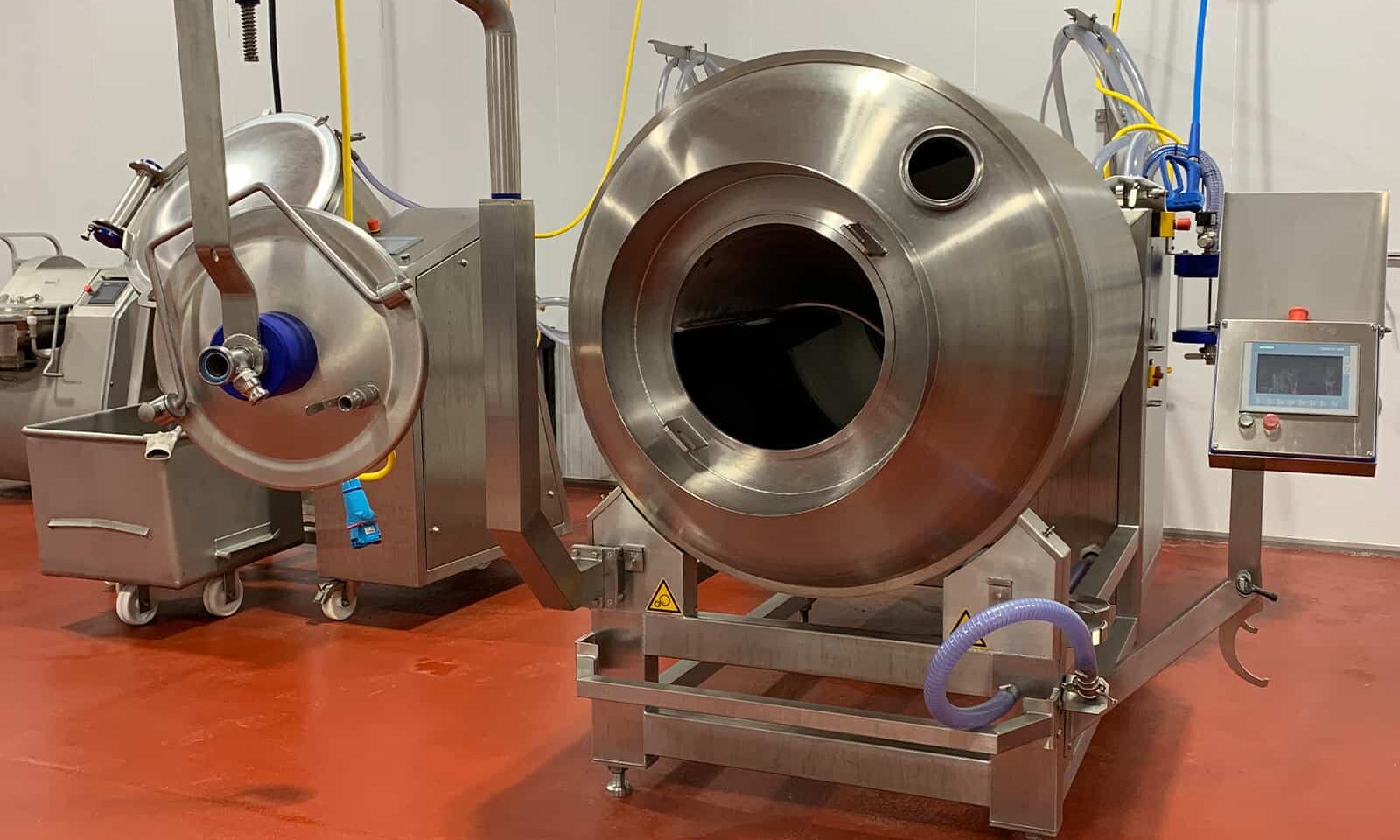

A meat vacuum tumbler is a specialized piece of equipment designed to marinate and tenderize meat products in a controlled environment. The core components typically include a rotating drum, a vacuum system, and a control panel. Meat, along with marinade, spices, and other ingredients, is placed inside the drum. A vacuum is then created within the drum, removing air from the chamber and from within the meat’s pores. The drum rotates, either continuously or intermittently, causing the meat to gently tumble. This mechanical action, combined with the vacuum environment, significantly accelerates the marination process and enhances the quality of the final product.

The principle behind its operation involves using the vacuum to expand the muscle fibers of the meat, allowing for deeper and more rapid penetration of the marinade. The tumbling action massages the meat, further aiding absorption and helping to break down tougher muscle tissues, resulting in a more tender product. It also facilitates the extraction of salt-soluble proteins to the surface of the meat, which can improve binding and reduce cook loss in processed meat products.

Meat vacuum tumblers are available in various sizes and configurations, but several key features are common across most models designed for commercial use:

The adoption of meat vacuum tumbler technology offers a multitude of advantages for meat processors, contributing to both product enhancement and operational efficiency.

Enhanced Marinade Absorption and Flavor Profile: The primary benefit is the significant improvement in marinade uptake. The vacuum environment expands the meat’s cellular structure, creating more pathways for the marinade to penetrate deeply and evenly. This results in a more intensely flavored product compared to traditional static marination methods.

Improved Tenderness and Juiciness: The gentle massaging action of the tumbling process helps to break down muscle fibers and connective tissues. This physical tenderization, combined with the enzymatic action of certain marinade ingredients, leads to a noticeably more tender product. Enhanced moisture retention due to deeper marinade penetration also contributes to a juicier end product after cooking.

Increased Product Yield: Marinades add moisture and weight to the meat. Effective absorption facilitated by vacuum tumbling can lead to higher product yields, as the meat retains more of the marinade. This can also translate to reduced cooking losses, as the well-marinated meat tends to lose less moisture during the cooking process.

Reduced Marination Time: Compared to soaking meat in marinade for extended periods (static marination), vacuum tumbling can reduce marination times from many hours or even days to just a matter of minutes or a few hours. This acceleration of the process significantly improves production throughput and allows for more flexible scheduling.

Consistent Product Quality: The controlled environment and programmable parameters of a vacuum tumbler ensure that each batch of meat is processed under identical conditions. This leads to a highly consistent product in terms of flavor, tenderness, color, and overall quality, which is crucial for brand reputation and customer satisfaction.

Improved Binding and Texture for Processed Meats: For products like sausages, restructured meats, or deli items, the tumbling process helps to extract salt-soluble proteins to the surface of the meat pieces. These proteins become sticky and act as a natural binder when the meat is cooked or further processed, improving sliceability, texture, and reducing “cook-out” or purge.

Operational Efficiency and Cost Savings: While representing an initial investment, vacuum tumblers can lead to long-term cost savings through reduced labor requirements for marination, more efficient use of marinades (less waste), faster processing times, and higher product yields.

Meat vacuum tumblers are versatile machines used across various sectors of the meat, poultry, and seafood industries. Their applications span a wide range of products:

The scale of application ranges from small artisanal producers and butcher shops using smaller capacity tumblers to large industrial processing plants employing multiple high-capacity machines integrated into their production lines.

Choosing the right meat vacuum tumbler requires careful consideration of several factors to ensure it meets the specific needs of a processing operation:

The effectiveness of vacuum tumbling is rooted in basic physical and chemical principles. When a vacuum is applied, the air within the drum and, more importantly, within the porous structure of the meat, is evacuated. This creates a pressure differential. The subsequent release of the vacuum, or the tumbling action under vacuum, causes the marinade to be drawn into the spaces previously occupied by air. The expansion of muscle fibers under vacuum increases the surface area available for marinade contact.

The mechanical energy imparted by the tumbling action serves multiple purposes. It constantly exposes new surfaces of the meat to the marinade, ensuring even distribution. The gentle massaging effect helps to physically break down tougher muscle structures and connective tissue, contributing to tenderness. Furthermore, for cured or restructured products, this mechanical action combined with salt in the marinade facilitates the extraction of myofibrillar proteins (actin and myosin). These proteins form a tacky exudate on the surface of the meat pieces, which, upon heating, coagulates and binds the pieces together, improving texture, sliceability, and water-holding capacity.

The meat vacuum tumbler machine has become an indispensable tool in the modern meat processing landscape. Its ability to significantly reduce marination times, improve marinade absorption, enhance product tenderness and juiciness, and increase overall yield makes it a valuable asset for businesses aiming to produce high-quality, consistent meat products. By carefully selecting a machine that fits their specific operational needs, meat processors can leverage this technology to improve efficiency, create superior value-added products, and maintain a competitive edge in the market. The consistent results and operational benefits offered by vacuum tumbling underscore its importance in achieving optimal processing outcomes and meeting consumer expectations for quality and flavor.