10 years of experience as a food machinery equipment manufacturer

10 years of experience as a food machinery equipment manufacturer

The landscape of modern food processing, particularly within the meat industry, is continually evolving. Efficiency, product quality, and consistency are paramount for businesses looking to thrive. One piece of equipment that has become increasingly integral to achieving these goals, especially for meat processors, butchers, and even larger culinary establishments in the UK, is the vacuum meat tumbler.

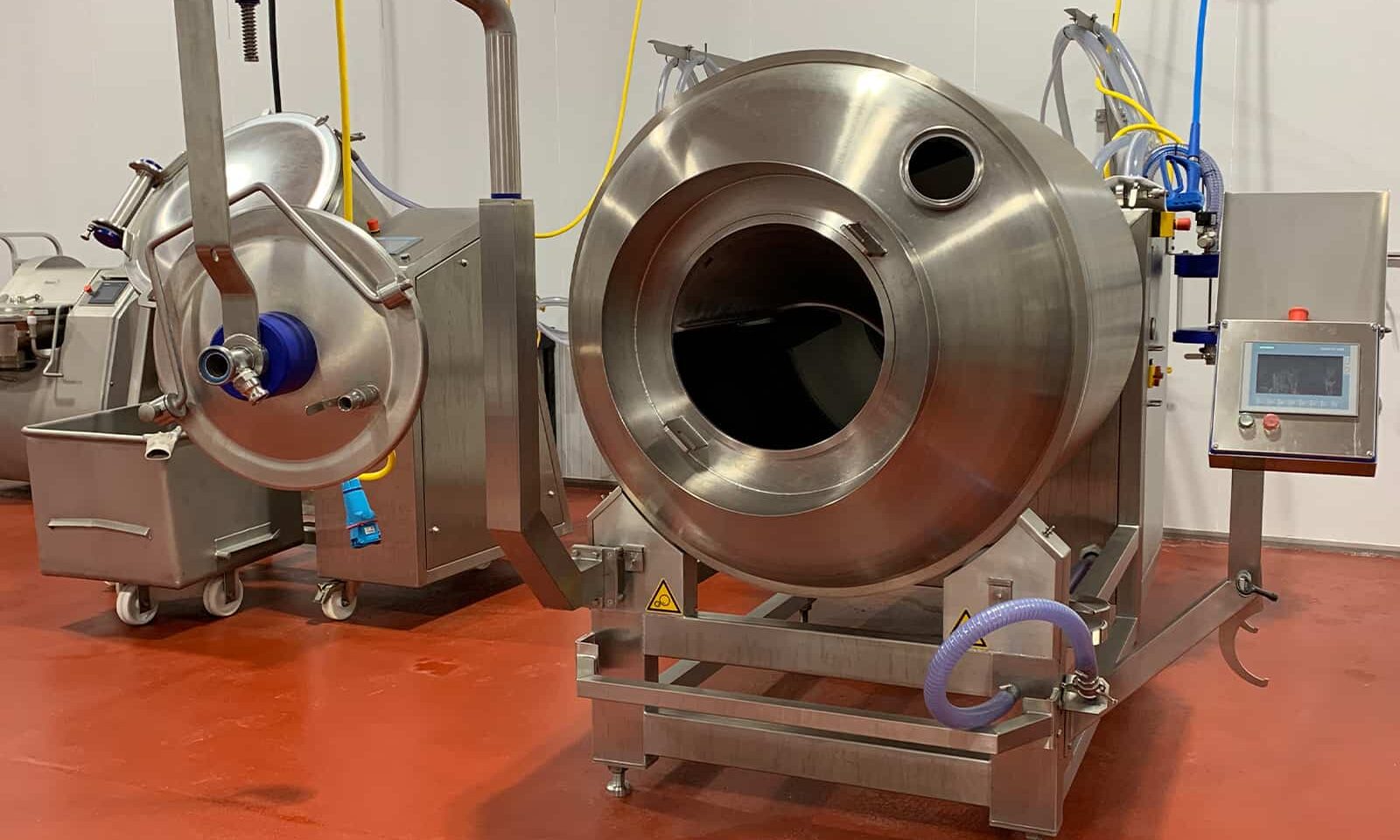

Vacuum meat tumblers are sophisticated machines designed to marinate, tenderise, and improve the overall quality of various meat products. The fundamental principle involves placing meat, along with marinade, spices, or curing agents, into a rotating drum. A vacuum is then created within this drum, which serves several crucial purposes. Firstly, the removal of air expands the muscle fibres of the meat, allowing for deeper and more rapid penetration of the marinade. Secondly, the vacuum environment can reduce microbial growth and limit oxidation, potentially extending the shelf life and preserving the colour of the product.

The tumbling action itself is a critical component. As the drum rotates, the meat products are gently lifted and dropped. This mechanical agitation works in synergy with the vacuum environment. It helps to further break down tough muscle tissues and evenly distribute the marinade or cure throughout the product. The result is a more tender, flavourful, and often juicier end product.

Businesses in the UK employing vacuum tumbling technology report a range of benefits:

The versatility of vacuum meat tumblers means they find application across various segments of the UK meat industry:

Butcher Shops: Artisan and traditional butchers are increasingly adopting smaller vacuum tumblers. This allows them to create value-added products like uniquely flavoured sausages, marinated chicken portions, home-cured bacon, and gammon. It provides a point of differentiation and can increase profit margins on standard cuts.

Restaurants and Catering: Larger restaurants and catering operations can benefit from the consistency and speed offered by these machines. Preparing large batches of marinated meats for grilling, roasting, or specific ethnic cuisines becomes more efficient, ensuring consistent quality even during peak service times.

Small to Medium-Scale Processors: For businesses producing cured meats, deli products, or ready-to-cook meal components, vacuum tumblers are indispensable. They enable efficient production of items like corned beef, pastrami, and various marinated poultry or red meat products for retail or foodservice supply.

Specialty Meat Production: Producers of items like jerky, biltong, or specialty cured hams also utilize tumbling to ensure even distribution of cures and spices, as well as to achieve desired textural properties.

For UK businesses considering investing in a vacuum meat tumbler, several factors warrant careful consideration:

As consumer demand for high-quality, flavourful, and convenient meat products continues to grow, technologies like vacuum tumbling will play an even more significant role. They empower UK businesses to innovate, improve product characteristics, and operate more efficiently. The ability to enhance tenderness, infuse deep flavours, and ensure product consistency provides a competitive edge in a discerning market.

In conclusion, the vacuum meat tumbler is more than just a piece of equipment; it is a strategic tool for meat processors in the UK aiming to elevate their product offerings. By understanding its principles and carefully selecting a machine that fits their operational needs, businesses can unlock significant improvements in product quality, processing efficiency, and ultimately, customer satisfaction.