10 years of experience as a food machinery equipment manufacturer

10 years of experience as a food machinery equipment manufacturer

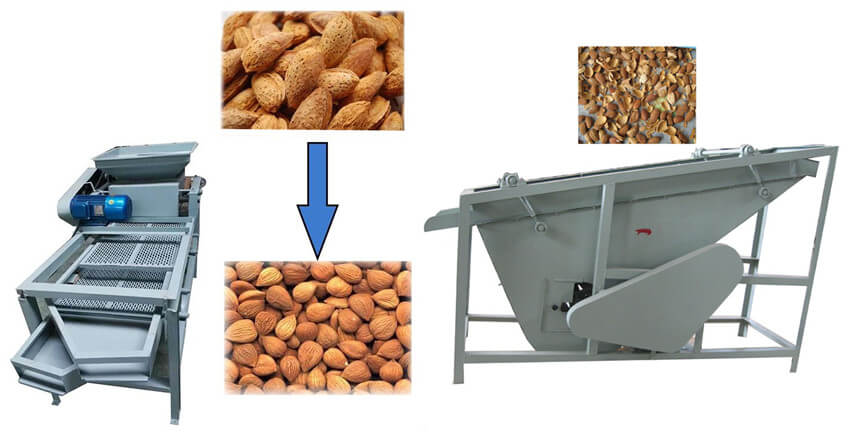

The almond processing industry faces unique challenges when it comes to efficiently and reliably reducing nuts into consistent pastes, flours, or chunks. Selecting the right heavy-duty almond crushing machine is often critical for businesses aiming to scale production, improve product quality, and optimize operational costs.

Commercial almond processing demands robust equipment capable of handling significant volumes consistently. Unlike smaller, consumer-grade devices, industrial crushers are engineered for endurance and high output. Key features commonly sought after include:

Investing in industrial almond crushing equipment unlocks several potential business models, each with distinct operational structures and revenue streams:

Selecting the optimal heavy-duty almond crushing machine is intrinsically linked to the chosen business model. Beyond basic specifications, consider these critical factors:

Implementing a heavy-duty almond crushing machine represents a significant operational step for processors and entrepreneurs. Thorough due diligence is paramount. Potential buyers should:

Selecting and integrating a suitable heavy-duty almond crushing machine is a strategic decision that can enhance efficiency, expand service offerings, and open up new revenue streams. Understanding the capabilities of this core equipment and its role within various operational frameworks is the foundation for a viable and sustainable almond processing business. Careful assessment of both the machinery and the targeted market opportunity is essential for achieving long-term operational goals.