10 years of experience as a food machinery equipment manufacturer

10 years of experience as a food machinery equipment manufacturer

In the realm of food processing, particularly within the meat industry, the meat massage vacuum tumbler has emerged as a pivotal piece of equipment. This machinery plays a crucial role in enhancing the quality, texture, and flavor of various meat products, contributing significantly to both small-scale and large-scale operations.

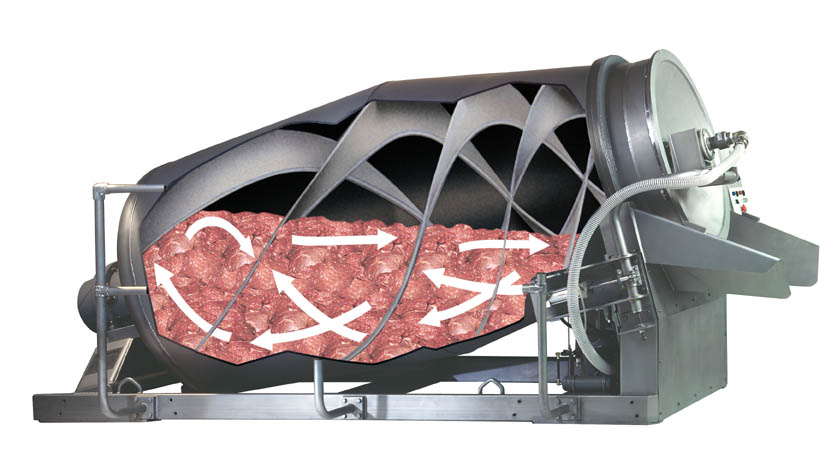

A meat massage vacuum tumbler is designed to simulate the traditional hand-massaging techniques used to tenderize and flavor meat. By placing meat cuts into a rotating drum under vacuum conditions, the tumbler facilitates the absorption of marinades, seasonings, and brines deep into the muscle tissue. The vacuum environment helps to remove air pockets within the meat, leading to improved protein extraction and binding.

The adoption of meat massage vacuum tumblers in the meat processing industry has several notable advantages:

Meat massage vacuum tumblers find applications in a wide range of meat processing operations, including:

Selecting the appropriate meat massage vacuum tumbler requires careful consideration of several factors:

The meat massage vacuum tumbler has revolutionized the meat processing industry by providing a more efficient and effective way to marinate, tenderize, and flavor meat products. Its ability to enhance flavor, improve product yield, and extend shelf life makes it an indispensable tool for meat processors of all sizes. As technology continues to advance, meat massage vacuum tumblers are likely to become even more sophisticated, further optimizing meat processing operations and enhancing the quality of meat products worldwide.