10 years of experience as a food machinery equipment manufacturer

10 years of experience as a food machinery equipment manufacturer

The landscape of modern food processing, particularly in the meat industry, is continually evolving, driven by the dual demands of efficiency and product quality. One piece of equipment that has become increasingly pivotal in achieving these goals is the automatic vacuum meat tumbler. This technology offers a sophisticated method for marinating, tenderizing, and improving the overall characteristics of various meat products, from poultry and beef to pork and seafood.

At its core, an automatic vacuum meat tumbler is designed to optimize the interaction between meat and marinades or brines. The process involves placing meat into a rotating drum, from which air is then evacuated to create a vacuum. This vacuum environment is crucial; it causes the muscle fibers of the meat to expand and separate. This expansion creates more surface area and internal pathways, allowing marinades and curing agents to penetrate the meat more deeply and uniformly than traditional static marination methods.

The “tumbling” aspect refers to the gentle, yet persistent, mechanical action of the rotating drum. As the drum rotates, the meat pieces are lifted and then fall, or “tumble,” against each other and the sides of the drum. This action serves multiple purposes. Firstly, it ensures that all surfaces of the meat are consistently exposed to the marinade. Secondly, the physical impact helps to break down tough muscle fibers and connective tissues, leading to a more tender final product. This mechanical tenderization works in synergy with the enzymatic or acidic components often found in marinades.

The adoption of automatic vacuum meat tumblers in commercial food processing environments offers a range of significant benefits:

The utility of automatic vacuum meat tumblers extends across various sectors of the food industry. Large-scale meat processing plants utilize these machines to enhance the quality and yield of products like ham, bacon, corned beef, and marinated chicken portions. Butcher shops and smaller artisanal producers can leverage tumblers to create value-added products, offering customers premium marinated or tenderized cuts.

Restaurants and catering services also find these machines beneficial for preparing consistently high-quality meat dishes efficiently. The ability to quickly marinate and tenderize meats allows for better menu planning and can elevate the dining experience. Even in the seafood industry, gentle tumbling under vacuum can be used to infuse flavors into fish and shellfish without damaging their delicate structures.

When considering an automatic vacuum meat tumbler, several operational aspects and features are important. The capacity of the drum is a primary consideration, and it should align with the production volume requirements of the facility. Construction material is also critical, with food-grade stainless steel being the industry standard due to its durability, resistance to corrosion, and ease of cleaning.

Modern tumblers often come equipped with programmable logic controllers (PLCs) that allow operators to set and store various processing cycles. These parameters can include total processing time, tumbling duration, rest periods (allowing the meat to absorb marinade without mechanical action), vacuum level, and drum rotation speed and direction (e.g., continuous or intermittent, clockwise or counter-clockwise). Some advanced models may also feature internal temperature monitoring and cooling jackets to maintain optimal product temperature during processing, which is crucial for food safety and quality, especially for extended cycles.

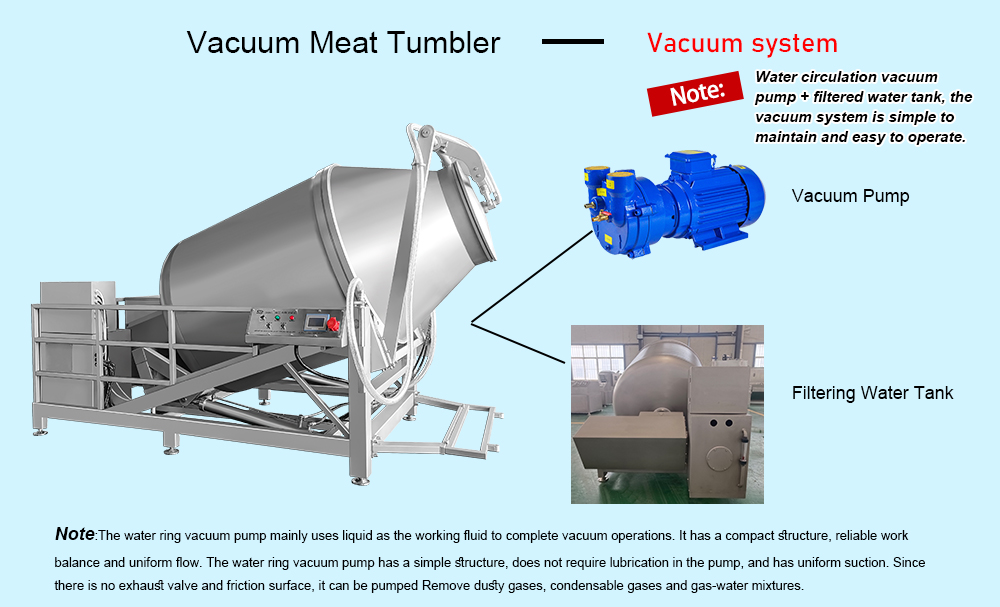

The quality and reliability of the vacuum pump are essential for the machine’s effectiveness. A robust vacuum system ensures that the desired vacuum levels are achieved quickly and maintained consistently. Ease of cleaning is another vital feature; designs that allow for straightforward disassembly of relevant parts or incorporate clean-in-place (CIP) systems can significantly reduce downtime and ensure hygienic operation.

In conclusion, the automatic vacuum meat tumbler represents a significant technological advancement in meat processing. By combining the principles of vacuum science and mechanical action, these machines offer a highly effective method for improving meat quality, increasing operational efficiency, and enhancing product consistency. For businesses in the food industry looking to optimize their marination and tenderization processes, the automatic vacuum meat tumbler is an investment that can yield substantial returns in terms of product excellence and operational productivity.