10 years of experience as a food machinery equipment manufacturer

10 years of experience as a food machinery equipment manufacturer

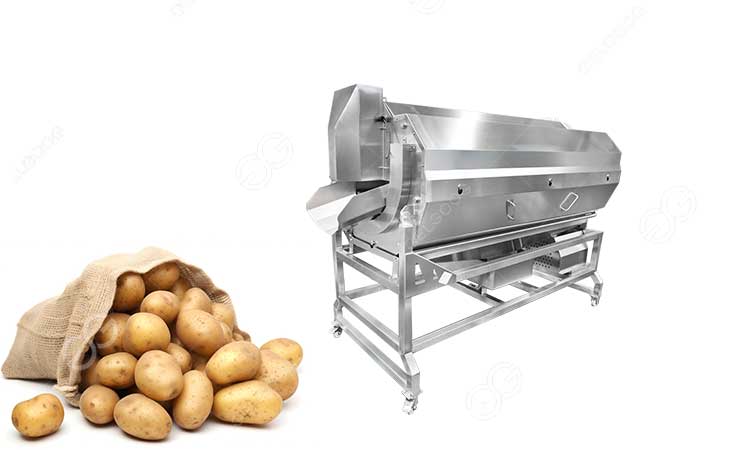

Within the agricultural processing sector, achieving higher yields with efficient resource utilization remains a constant pursuit. Machinery designed specifically for root vegetable cleaning plays a pivotal role in this equation. The performance of the “1500sand” machine potato cleaner is often evaluated against this backdrop, focusing on its contribution to operational speed and potential yield enhancement.

Manual potato cleaning, while traditional, presents significant bottlenecks. It’s labor-intensive, time-consuming, and often leads to inconsistent results. Bruising or inefficient dirt removal can directly impact the final usable yield per harvest. Automated cleaners address these pain points directly, aiming for a faster, more uniform process.

The 1500sand potato cleaner enters this context as a machine engineered for efficiency. Its design principles revolve around:

The core efficiency proposition hinges on processing speed. Observations suggest the 1500sand machine significantly outpaces manual cleaning methods. For large-scale farms or cooperative packhouses facing peak season demands, this rapid throughput translates directly to getting potatoes graded, packed, and to market faster.

Speed, however, is only meaningful when paired with cleaning efficacy. Yield improvement isn’t just about washing more potatoes; it’s about preserving as much of the harvest as possible. By minimizing damage through gentle agitation and ensuring a consistent clean, the machine contributes to retaining a higher proportion of salable product. Reduced waste – potatoes discarded due to bruising or insufficient cleaning – effectively increases the net usable yield per ton harvested. Furthermore, a faster cleaning cycle potentially allows for quicker field clearance and potentially influences future planting schedules.

Efficiency encompasses more than raw processing speed:

The efficiency gains translate into tangible economic benefits. Faster processing reduces the per-unit cost of cleaning. When combined with the potential yield preservation achieved through reduced damage and waste, the overall cost per unit of usable, saleable potato output improves. For businesses operating on thin margins, optimizing the efficiency of each step, including cleaning, is crucial for competitiveness.

Scaling operations effectively often depends on the capacity of the slowest link in the chain. A high-efficiency potato cleaner like the 1500sand ensures that the cleaning stage doesn’t become a limiting factor as farms expand or processing volumes increase.

Determining the precise increase in yield attributable solely to a potato cleaner involves comparing operational metrics before and after implementation. Key Performance Indicators (KPIs) would include:

The “1500sand” potato cleaner represents a technological solution designed explicitly to enhance efficiency at a critical post-harvest juncture. Its primary contribution lies in accelerating the cleaning process significantly, thereby increasing throughput and aiding in overall workflow speed. Crucially, through gentle yet effective cleaning that minimizes bruising and waste, it supports the goal of maximizing the net usable yield derived from each harvest. While numerous factors influence farm profitability, the integration of efficient processing equipment like this cleaner is widely recognized as a key component in streamlining operations, preserving crop value, and improving the economic viability of potato production and processing.