10 years of experience as a food machinery equipment manufacturer

10 years of experience as a food machinery equipment manufacturer

Customized Vacuum Tumblers for Meat Processing: Enhancing Efficiency and Quality

In the competitive landscape of the meat processing industry, the demand for efficient and high-quality products is paramount. One crucial piece of equipment that significantly contributes to achieving these goals is the vacuum tumbler. While standard vacuum tumblers serve a general purpose, customized options offer unique advantages tailored to the specific needs of individual meat processors. This article explores the benefits and considerations of utilizing customized vacuum tumblers in meat processing operations.

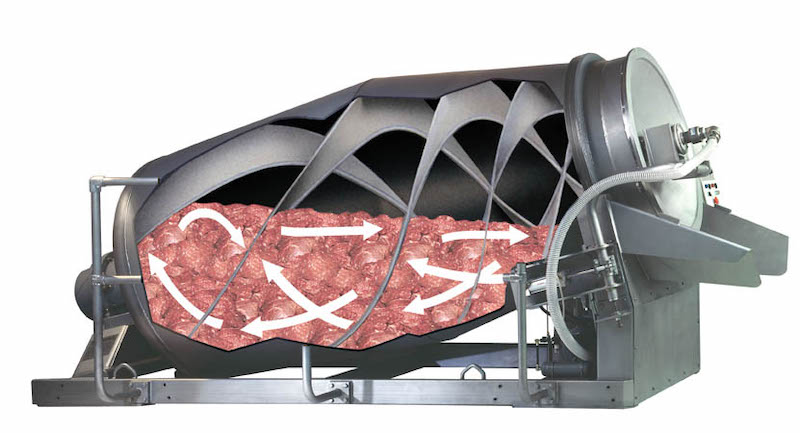

A vacuum tumbler is a specialized machine designed to enhance the marination, tenderization, and overall quality of meat products. It operates by gently tumbling meat under vacuum, which opens up the muscle fibers, allowing for better absorption of marinades and seasonings. This process results in improved flavor, texture, and moisture retention in the final product.

While standard vacuum tumblers are effective, customization takes the process a step further, offering several distinct advantages:

When considering a customized vacuum tumbler, several factors should be carefully evaluated:

The process of customizing a vacuum tumbler typically involves the following steps:

Customized vacuum tumblers represent a valuable investment for meat processors seeking to enhance efficiency, improve product quality, and reduce waste. By tailoring the tumbler’s design and operation to their specific needs, processors can achieve superior results and gain a competitive edge in the market. Careful consideration of the key factors outlined above, along with the selection of a reputable supplier, will ensure a successful customization process and a significant return on investment.