10 years of experience as a food machinery equipment manufacturer

10 years of experience as a food machinery equipment manufacturer

The global demand for conveniently packaged and hygienically preserved meat products continues to grow. Lamb meat rolls, a popular choice for consumers due to their versatility and ease of preparation, require specific packaging solutions to maintain freshness, extend shelf life, and enhance consumer appeal. The lamb meat roll film packaging machine has emerged as a critical piece of equipment in the meat processing industry, addressing these needs with efficiency and precision.

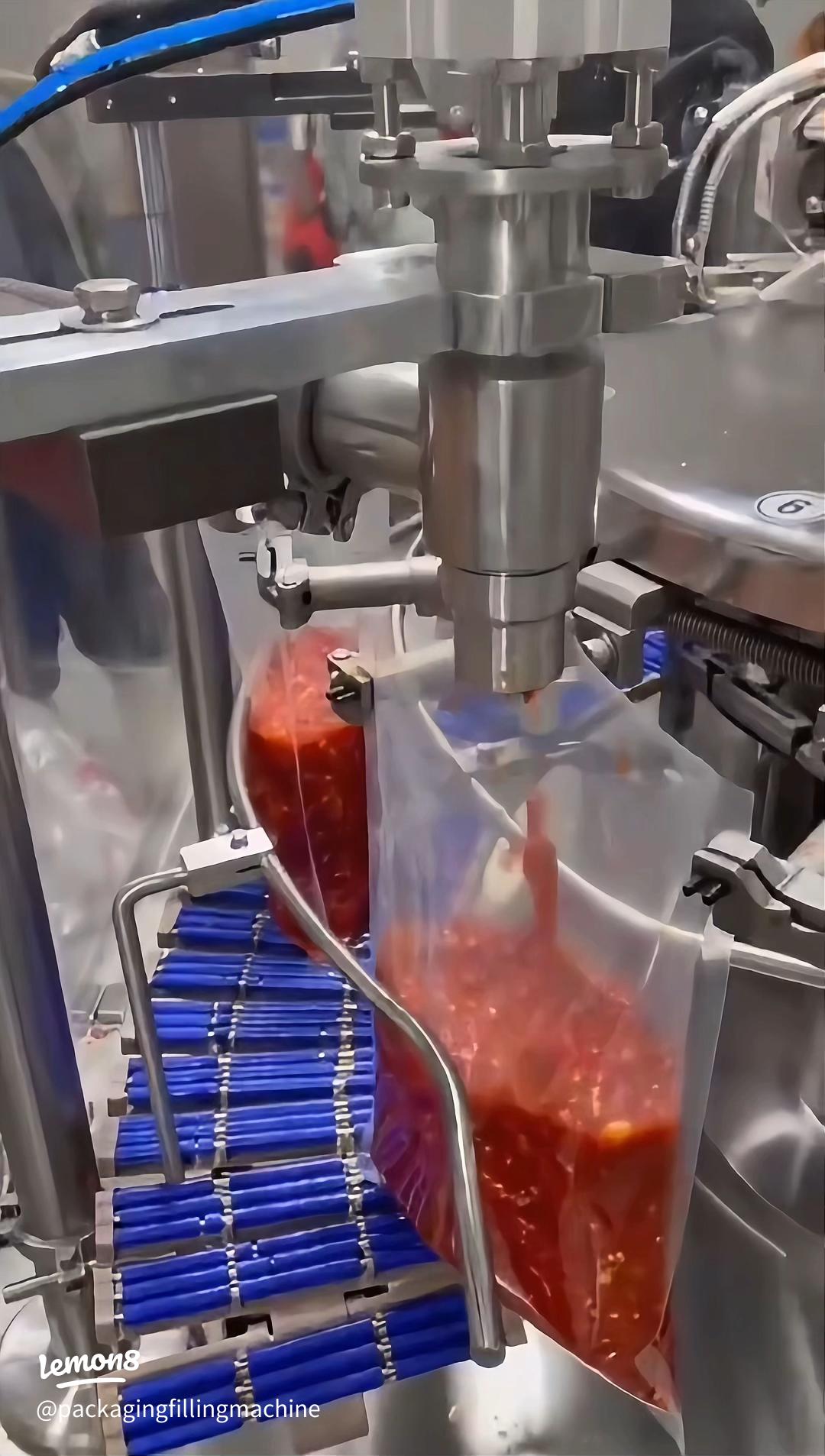

A lamb meat roll film packaging machine is an automated or semi-automated system designed specifically to wrap lamb meat rolls, and often similar cylindrical meat products, in flexible packaging film. These machines typically employ technologies such as thermoforming, flow wrapping, or vacuum packaging to create a secure, airtight seal around the product. The primary goal is to protect the meat from external contaminants, oxidation, and moisture loss, thereby preserving its quality, flavor, and safety for a longer duration.

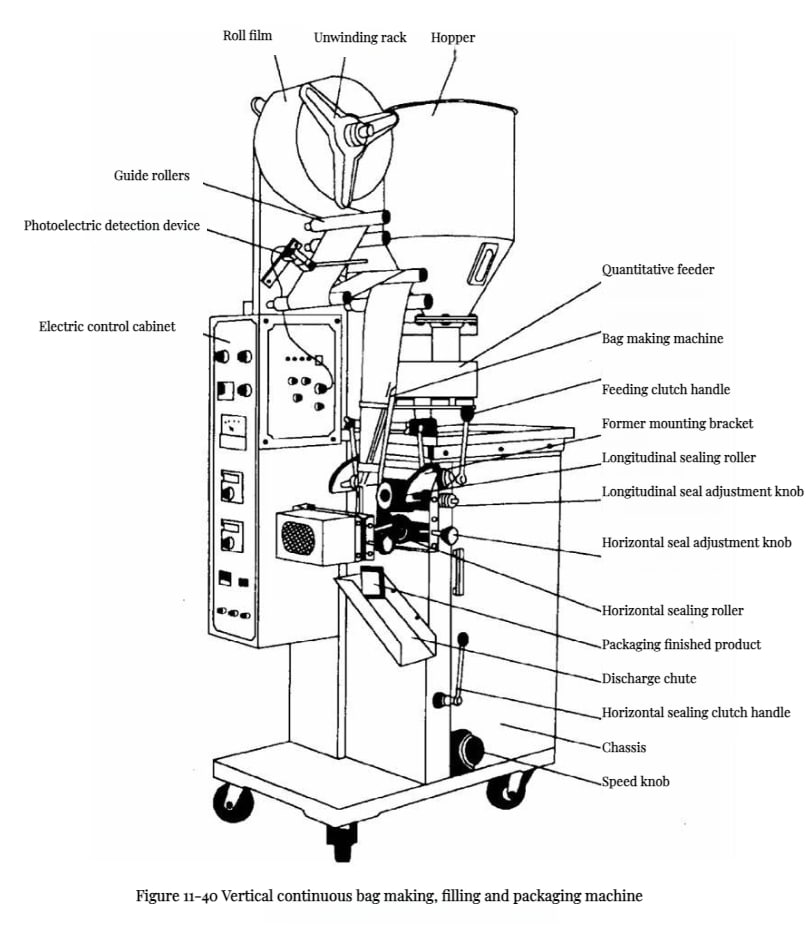

The operational principle usually involves several key stages. First, the packaging film, supplied in rolls, is unwound and fed into the machine. Depending on the machine type (e.g., thermoforming), a bottom web of film might be heated and formed into a tray or cavity. The lamb meat rolls are then accurately placed into these formed cavities or onto a flat web of film (in flow wrapping). Subsequently, a top web of film is applied, and the package is sealed, often incorporating vacuum extraction or modified atmosphere packaging (MAP) technologies before the final seal is made. Finally, the individual packages are cut and separated.

Modern lamb meat roll film packaging machines offer a host of features that translate into significant advantages for meat processors.

When considering the acquisition of a lamb meat roll film packaging machine, several factors come into play. The required production capacity is a primary determinant; smaller operations might opt for semi-automatic models, while larger facilities will benefit from fully automated, high-speed lines. The specific type of packaging desired—whether simple overwrapping, vacuum packaging, or MAP—will also dictate the choice of machine technology.

The machine’s footprint and its integration with existing production lines are important logistical considerations. Ease of operation, maintenance requirements, and the availability of technical support and spare parts from the manufacturer are crucial for ensuring long-term operational reliability and minimizing downtime. Furthermore, compatibility with preferred packaging films and the ability to adapt to potential future changes in product dimensions or packaging styles should be assessed.

Sanitation and Cleanability are paramount in meat processing. Machines designed with smooth surfaces, minimal crevices, and easily accessible components for cleaning will help maintain high hygiene standards and comply with food safety regulations. The build quality, typically involving robust stainless steel construction, ensures durability in demanding processing environments.

The adoption of specialized film packaging machines for lamb meat rolls has had a considerable impact on the meat industry. It has enabled processors to extend their market reach by offering products with longer shelf lives, suitable for wider distribution networks. The enhanced presentation and guaranteed freshness contribute to increased consumer confidence and brand loyalty.

Moreover, the efficiency gains allow businesses to scale their operations more effectively, responding to fluctuating market demands without a proportional increase in labor. The ability to incorporate MAP technology also allows for the preservation of the meat’s natural color and texture, aspects highly valued by consumers. This technology helps to maintain the desirable red color of lamb meat for longer periods, preventing premature browning that can deter purchases, even if the product is still safe to consume.

As sustainability becomes an increasingly important focus, manufacturers of these packaging machines are also exploring ways to optimize film usage and ensure compatibility with more environmentally friendly packaging materials. The precision of these machines helps in reducing overall packaging material consumption compared to less controlled methods.

The lamb meat roll film packaging machine represents a significant technological advancement for the meat processing sector. Its ability to combine product protection, extended shelf life, operational efficiency, and enhanced product presentation makes it an indispensable asset for businesses aiming to deliver high-quality lamb meat products to the market. As consumer expectations for food safety, quality, and convenience continue to rise, the role of such sophisticated packaging solutions will only become more critical. Investing in the right packaging machinery is not just about wrapping a product; it is about ensuring its integrity, appeal, and viability in a competitive marketplace. These machines empower processors to meet regulatory demands, optimize their production lines, and ultimately, satisfy the end consumer with a safe, fresh, and appealing product.