10 years of experience as a food machinery equipment manufacturer

10 years of experience as a food machinery equipment manufacturer

Indonesia, an archipelago renowned for its rich marine biodiversity, stands as one of the world’s leading producers and exporters of fish and seafood products. The sheer volume of catch necessitates efficient processing methods to maximize yield, maintain quality, and meet both domestic and international demand. Central to modernizing this sector is the adoption of specialized machinery, among which the fish meat separator, also known as a fish deboner or meat-bone separator, plays a pivotal role.

Traditionally, the task of separating fish meat from bones, skin, and scales was a labor-intensive, time-consuming process. Manual deboning, while precise if done carefully, is often slow, can lead to significant wastage of edible meat, and presents challenges in maintaining consistent hygiene standards, especially in large-scale operations. The introduction of fish meat separator technology has offered a transformative solution to these challenges, significantly impacting the Indonesian seafood processing industry.

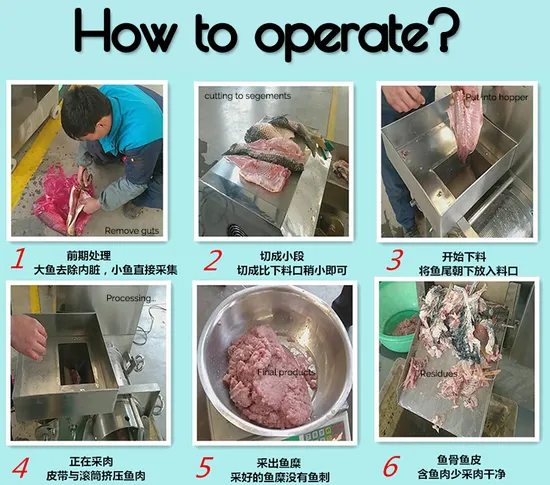

A typical fish meat separator operates on a relatively straightforward yet effective mechanical principle. Fish, often pre-cut or whole (depending on the machine’s size and design), are fed into the machine. Inside, they encounter a system usually comprising a perforated drum and a flexible belt, often made of food-grade rubber or polyurethane. The belt presses the fish against the rotating perforated drum. The pressure extrudes the soft fish flesh through the small holes of the drum, while the bones, skin, and scales, being more rigid, remain on the outer surface of the drum and are subsequently scraped off and discharged separately.

The resulting product is minced fish meat, largely free of bones and skin. The fineness of the mince can often be adjusted by changing the drum’s perforation size. These machines are typically constructed from stainless steel, ensuring durability, resistance to corrosion from saltwater and fish oils, and compliance with food safety standards, making them easy to clean and sanitize.

The adoption of fish meat separators offers a multitude of benefits to Indonesian fish processors, from small-scale enterprises to large industrial plants.

Enhanced Efficiency and Yield: One of the most significant advantages is the dramatic increase in processing speed and meat recovery. These machines can process hundreds to thousands of kilograms of fish per hour, far exceeding manual capabilities. Moreover, they are highly efficient at extracting meat, often recovering flesh that would be difficult or impossible to retrieve by hand, thereby minimizing waste and maximizing the usable portion of the catch. This is particularly crucial for utilizing smaller fish or species that are challenging to debone manually.

Improved Product Quality and Consistency: Automated separation can lead to a more consistent product in terms of texture and bone content. While not always achieving 100% bone removal (fine pin bones can sometimes pass through depending on settings and fish type), the reduction is substantial, leading to a higher quality raw material for various value-added products like fish balls, fish cakes, surimi, fish sausages, fish nuggets, and pet food.

Labor Optimization and Cost Reduction: While these machines represent an initial investment, they can lead to significant long-term cost savings by reducing the reliance on manual labor for deboning. This allows businesses to reallocate human resources to other critical areas of production, quality control, or value addition. In a competitive global market, such operational efficiencies are vital.

Contribution to Food Safety: The use of stainless steel and the reduction in manual handling of the fish meat contribute to improved hygiene and food safety. Enclosed systems minimize exposure to airborne contaminants, and the ease of cleaning helps prevent bacterial growth, a critical factor in processing perishable goods like fish.

Valorization of Byproducts: The separated bones and skin are not necessarily waste. They can be collected and further processed into fish meal for aquaculture feed, fish bone powder as a calcium supplement, or used for producing fish stock and broths, adding another revenue stream and contributing to a more circular economy within the seafood industry.

When Indonesian businesses consider investing in fish meat separators, several factors come into play. The capacity of the machine (kg/hour) must align with the processor’s volume requirements. The type of fish predominantly processed also matters, as different species might require slight adjustments or specific machine configurations for optimal results. Build quality, particularly the grade of stainless steel used (e.g., SUS304 or SUS316), is crucial for longevity and hygiene. Ease of operation, cleaning, and maintenance are also important practical considerations, as is the availability of spare parts and technical support, whether from local manufacturers or international suppliers with representation in Indonesia.

Many Indonesian seafood processing companies, particularly Small and Medium Enterprises (SMEs), have benefited immensely from this technology. It allows them to scale up production, improve the quality of their offerings, and compete more effectively. The Indonesian government, through various ministries, often supports the modernization of the fisheries sector, which can include facilitating access to such processing technologies.

The integration of fish meat separators is more than just an operational upgrade; it’s a component of the broader development of Indonesia’s seafood value chain. By enabling efficient primary processing, these machines support the growth of secondary processing industries that create value-added products. This, in turn, can lead to increased export earnings, job creation, and improved food security for the nation.

Furthermore, the ability to efficiently process a wider range of fish species, including underutilized ones, can help diversify the seafood industry and reduce pressure on more commonly targeted stocks. This aligns with sustainable fishing practices and resource management goals.

In conclusion, the fish meat separator represents a critical piece of technology for the Indonesian seafood industry. Its ability to enhance efficiency, improve yield and quality, reduce costs, and contribute to food safety makes it an invaluable asset for processors aiming to thrive in a dynamic and demanding market. As Indonesia continues to harness its vast marine resources, technologies like the fish meat separator will undoubtedly continue to play a significant role in shaping the future of its vibrant fisheries sector, underpinning its capacity to feed its population and supply global markets with high-quality seafood products.