10 years of experience as a food machinery equipment manufacturer

10 years of experience as a food machinery equipment manufacturer

The global demand for seafood continues to rise, placing increasing pressure on the fish processing industry to optimize operations, enhance yield, and maintain high standards of quality and hygiene. Manual fish processing, particularly deboning, is labor-intensive, time-consuming, and can lead to significant wastage of valuable fish meat. In response to these challenges, automated solutions have become increasingly vital. Among these, fish meat separators, also known as deboning machines or meat-bone separators, play a crucial role. One such example making its mark in the sector is the 350 fish meat separator, a model designed to address the specific needs of small to medium-scale fish processing operations.

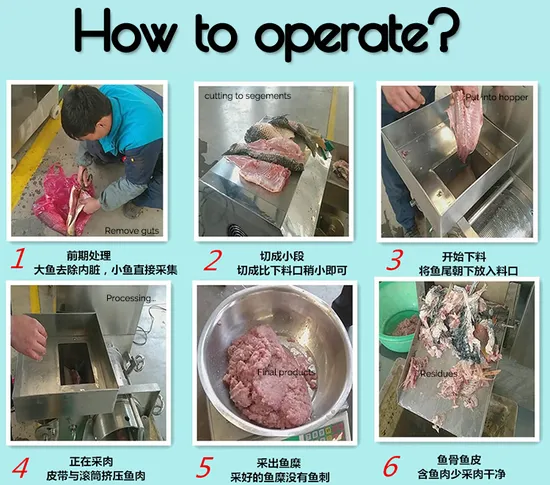

Before delving into the specifics of the 350 model, it is pertinent to understand the fundamental principles behind fish meat separation technology. These machines are designed to mechanically separate fish flesh from bones, skin, and fins. The general process involves feeding pre-cut or whole small fish into the machine. Inside, a combination of pressure and mechanical action, typically involving a perforated drum and a flexible belt, squeezes the fish. The soft flesh is extruded through the small perforations of the drum, while the harder components like bones and skin are retained and expelled separately. This process not only recovers meat that would be difficult or impossible to retrieve through manual deboning but also does so with remarkable speed and consistency.

The 350 fish meat separator is engineered with a focus on efficiency, durability, and ease of use, catering primarily to operations that require a robust yet manageable processing capacity. The “350” in its designation often alludes to a key performance metric, such as its processing capacity (e.g., up to 350 kilograms per hour, though this can vary by specific manufacturer interpretation) or a specific drum diameter or design characteristic that defines its operational scale.

Key operational features typically associated with a machine of this class include:

The adoption of a fish meat separator like the 350 model can bring forth a multitude of benefits for fish processing businesses.

Increased Yield: This is arguably the most significant advantage. These machines can recover a substantially higher percentage of fish meat compared to manual methods, especially from fish frames or species with complex bone structures. Meat clinging to bones, which is often discarded in manual operations, is efficiently harvested, turning potential waste into a valuable product.

Labor Cost Reduction: Manual deboning is a skilled and labor-intensive task. Automating this process with a machine like the 350 significantly reduces the need for manual labor, allowing businesses to reallocate human resources to other value-added tasks. This can lead to substantial savings in labor costs and address challenges related to labor shortages.

Improved Product Consistency: Mechanical separation produces minced fish meat with a generally uniform texture. This consistency is highly desirable for further processing into products like fish balls, fish cakes, surimi, fish sausages, patties, and fillings where texture and uniformity are critical quality attributes.

Enhanced Efficiency and Throughput: With a processing capacity suitable for small to medium enterprises, the 350 model can handle a significant volume of fish in a relatively short period, drastically improving overall throughput compared to manual deboning lines. This increased speed allows businesses to meet demand more effectively.

Versatility: While performance can vary with fish type, size, and pre-processing, fish meat separators like the 350 are often capable of processing a diverse range of fish species, both marine and freshwater. They can be used for whole small fish or for larger fish that have been headed, gutted, and perhaps cut into manageable pieces.

Better Hygiene and Food Safety: The use of food-grade stainless steel and the enclosed nature of the processing helps in maintaining better hygienic standards. Minimizing manual handling reduces the risk of contamination. Regular and thorough cleaning, facilitated by designs that allow easy disassembly, is essential to uphold these standards.

Value Addition: By recovering meat that might otherwise be discarded or sold at very low prices (e.g., for animal feed), the 350 fish meat separator allows processors to create higher-value products. The minced fish obtained can be a primary ingredient in a variety of consumer-ready food items.

The minced fish produced by the 350 fish meat separator serves as a versatile base ingredient for numerous applications:

While the benefits are clear, potential adopters of the 350 fish meat separator should consider several factors. The initial investment cost is a primary consideration, although this is often offset by labor savings and increased yield over time. The type of fish being processed is also important; very small, bony fish or fish with particularly tough skin might require specific adjustments or yield different results. Adequate training for operators on proper usage, cleaning, and basic maintenance is essential for optimal performance and longevity of the machine. Furthermore, businesses must ensure that their facility has the necessary space and power supply for the equipment.

The pre-processing of fish, such as heading and gutting for larger species, can also impact the efficiency and quality of the output. The quality of the final minced product can also be influenced by the freshness of the raw material and the operational parameters of the machine, such as belt tension and drum speed (if adjustable).

The 350 fish meat separator represents a category of equipment that offers a practical and efficient solution for enhancing the value and productivity of fish processing operations. By automating the deboning process, it enables businesses to achieve higher meat yields, reduce labor dependence, improve product consistency, and maintain better hygienic standards. For small to medium-sized seafood processors looking to scale up their operations, improve efficiency, and reduce waste, machinery like the 350 model presents a compelling option. As the industry continues to evolve towards greater automation and sustainability, the role of such specialized equipment will undoubtedly become even more significant in meeting the world’s growing appetite for seafood products.